How to cool down a power supply?

In the world of power supplies, heat dissipation is a crucial aspect that directly affects performance, reliability, and longevity. As electronic components continue to shrink in size while packing in more power, effective cooling methods are essential to prevent overheating and ensure optimal functioning. In this article, we delve into the fascinating realm of power supply cooling and explore the pros and cons of three popular methods: convection cooling, conduction cooling, and forced air cooling.

Convection Cooling: Harnessing the natural flow of air

Imagine a gentle breeze rustling through the trees on a warm summer day - nature's very own cooling system. Convection cooling takes inspiration from this phenomenon, utilizing the natural flow of air to dissipate heat.

Convection cooling is subject to the physical law of thermodynamics. Cooling takes place via passive heat exchange between the converter and the surrounding as the waste heat dissipates via the casing of the power supply. Simplicity reigns supreme in convection cooling. The absence of any additional components reduces complexity and cost, making it an economical choice. Moreover, the lack of mechanical components contributes to its reliability, as there are no moving parts that can fail, ensuring a longer lifespan. Furthermore, the silence it offers is a boon in noise-sensitive environments, where the tranquility of operation is paramount.

However, convection cooling soon reaches physical limitations as only a small amount of heat can be transferred through natural convection. And so, its cooling capacity is modest, making it more suitable for low-power applications. Additionally, its effectiveness relies on ambient conditions such as temperature and natural airflow, which can be unpredictable, posing challenges for consistent cooling performance.

Conduction Cooling: The Art of Direct Heat Transfer

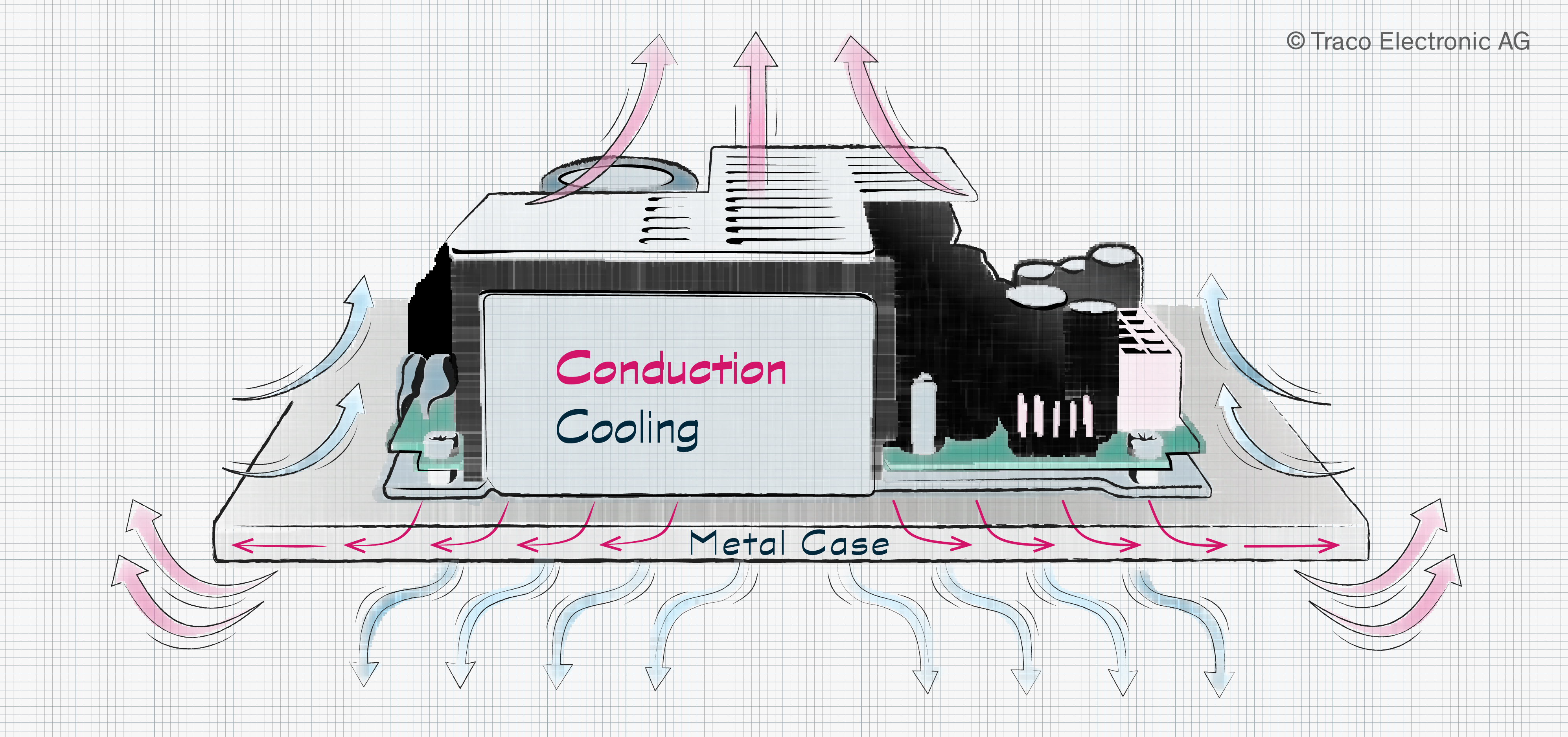

Imagine you're sitting on a cold winter's day, and you decide to warm up by placing your hands on a cozy cup of hot tea. As your palms make direct contact with the warm surface of the cup, you can feel the heat being transferred from the tea to your hands. Conduction cooling works on the same principle as your comforting cup of tea. It involves the direct transfer of heat from electronic components to a thermally conductive material, usually a heat sink or cooling plate. This heat sink, like your hands touching the cup, serves as a medium to carry away the heat, preventing the electronic components from overheating.

Conduction cooling exhibits remarkable efficiency in dissipating heat, making it a great choice for even high-power applications. By establishing direct contact between components and the heat sink/cooling plate, it ensures effective heat dissipation, elevating the overall reliability of the system. While the principal of the actual heat transfer to the surrounding is identical to convection cooling the much larger surface area achieved by the heat sink or cooling plate greatly increases its effectiveness. Existing metal cases of applications may also be used as a heatsink, making conduction cooled power supplies a flexible option in many applications. Like convection cooling, conduction cooling operates silently, as it does not rely on fans. This makes it ideal for applications where noise pollution is undesirable, such as in audio equipment or quiet workspaces.

Despite its strengths, conduction cooling also faces challenges. The overall cooling capacity is limited by the thermal resistance at the interface between the component and the heat sink or cooling plate. The success of conduction cooling depends on achieving good thermal contact between components and the heat sink. This involves intricate engineering and careful selection of materials, adding complexity to the design and manufacturing process which often leads to slightly higher prices for such power supplies. There are also physical limitations as even with an infinitely large cooling plate, as the heat spreads across the cooling plate, it encounters thermal resistance within the material itself. This resistance limits the rate at which heat can be dissipated from the power supply.

Forced Air Cooling: When a gentle breeze isn't enough

Imagine you're in a room on a hot summer day, and the heat is almost unbearable. Opening a window to let in a gentle breeze provides some relief, but it's just not cutting it anymore. It's at this point you decide to turn on a powerful electric fan, and suddenly, you're enveloped in a refreshing, cool airflow. This simple act of using forced air to combat the heat is akin to the world of electronics.

Forced air cooling, where fans take the center stage, is an active cooling method that excels in its ability to provide significant airflow, enabling efficient heat dissipation especially for high-power applications. With forced air cooling, the direction and rate of airflow can be controlled, allowing for targeted cooling of specific components or areas within the system. By adjusting the fan speed forced air cooling can adapt to varying ambient conditions like temperature. This flexibility is advantageous in complex electronic systems with varying cooling requirements. Compared to other active cooling methods like liquid cooling, forced air cooling is generally more cost-effective. It strikes a good balance between cooling efficiency and cost, making it a popular choice in many applications.

But with this raw power also come some trade-offs. The presence of fans introduces noise and vibrations to the system, which are inconvenient in many applications. Reliability concerns arise due to the potential failure of moving parts introduced with fans. A sudden failure of a fan can impact system performance or lead to a complete shutdown of an application. Routine maintenance, including cleaning fans and air filters, may be necessary to prevent dust accumulation and ensure optimal airflow. Systems also have to account for a controlled air intake and outtake to ensure optimal performance. Additionally, the need for fans and the associated components increases the system's overall volume, posing challenges in compact designs.

Conclusion: Choosing the appropriate cooling method

As technology races forward, pushing the boundaries of what is possible, the demands on cooling systems intensify. Engineers must navigate a complex landscape, balancing performance, reliability, cost, and noise considerations when determining the most suitable cooling approach. When selecting a cooling method, it is crucial to consider the specific requirements, constraints, and trade-offs of the electronic system at hand. By understanding the nuances of these cooling methods, engineers can make informed decisions, ensuring that electronic systems remain cool, efficient, and reliable, paving the way for innovations in the ever-evolving realm of electronics.