The standards that underpin EMC compliance

Fulfilling EMC can seem like an annoying extra hurdle in a product’s development that, perhaps just this time, we could skip. However, such a decision could lead to injury or even death. In a study conducted in 2007, researchers at the University of Amsterdam linked emissions from GPRS and UMTS cellular handsets to incidents with 43% of critical care medical devices tested, 33% of which were considered hazardous [Link].

It may seem odd that, in recent memory, such an EMC-related danger was possible. After all, the electronics industry’s battle with EMC dates back to the introduction of the telegraph and radio. So who defines the EMC rules, and what are they?

History of EMC standards

Despite the early recognition of EMC issues, it wasn’t until 1933 that the international standards committee CISPR (Comité International Spécial des Perturbations Radioélectriques), part of the IEC (International Electrotechnical Commission), was formed to address them. In the USA, it was even later. The IEEE EMC Society was formed in 1957, although Radio Frequency Interference (RFI) standards, such as IEEE Standard 140, focusing on minimizing emissions from RF heaters, was published in 1950 [Link].

Today, the IEC develops standards at the international level within the TC 77 technical committee [Link] and CISPR, with support from CENELEC, ISO, and others. These are then harmonized and transferred to the national level by local organizations (SEV, DIN, BSI, FCC, ANSI, and others).

What EMC standards apply to power supplies?

As a supplier, Traco Power’s products are typically seen as a component of a larger piece of equipment, termed apparatus in the specifications. This is because they are not used as standalone device but are built into our customer’s products. Thus, manufacturers of power supplies typically fulfill generic standards unless the product targets certain industry branches with more demanding requirements.

The EMC standards are classified into three broad groups: basic, generic, and product or family.

Basic standards cover general rules, including phenomenon, terminology, measurement and test setups, and compatibility levels. A series of such standards are IEC 61000-4-x. For example, IEC 61000-4-5 covers surge immunity testing.

Generic standards focus on specific environments, such as EMI in industrial and residential use cases. IEC 61000-6-1 covers immunity for residential, commercial, and light-industrial environments, while IEC 61000-6-3 is the reference for emissions. IEC 61000-6-2 and 61000-6-4 cover immunity and emissions for industrial environments.

Industrial immunity limits are higher than residential limits, while the reverse is true for emission limits. Since power supplies are often a component, fulfilling the stricter standard delivers a more robust product. However, for a custom design, there may be a need to balance cost and size against EMC performance, leading to the use of the less strict standard.

Product-specific standards address the needs of applications in specific industries, such as railway and medical. These cover test levels and performance compatibility in coordination with generic standards. A relevant example is EN 50121-3-2, covering electromagnetic compatibility for railway rolling stock apparatus or EN 60601-1-2 for medical devices.

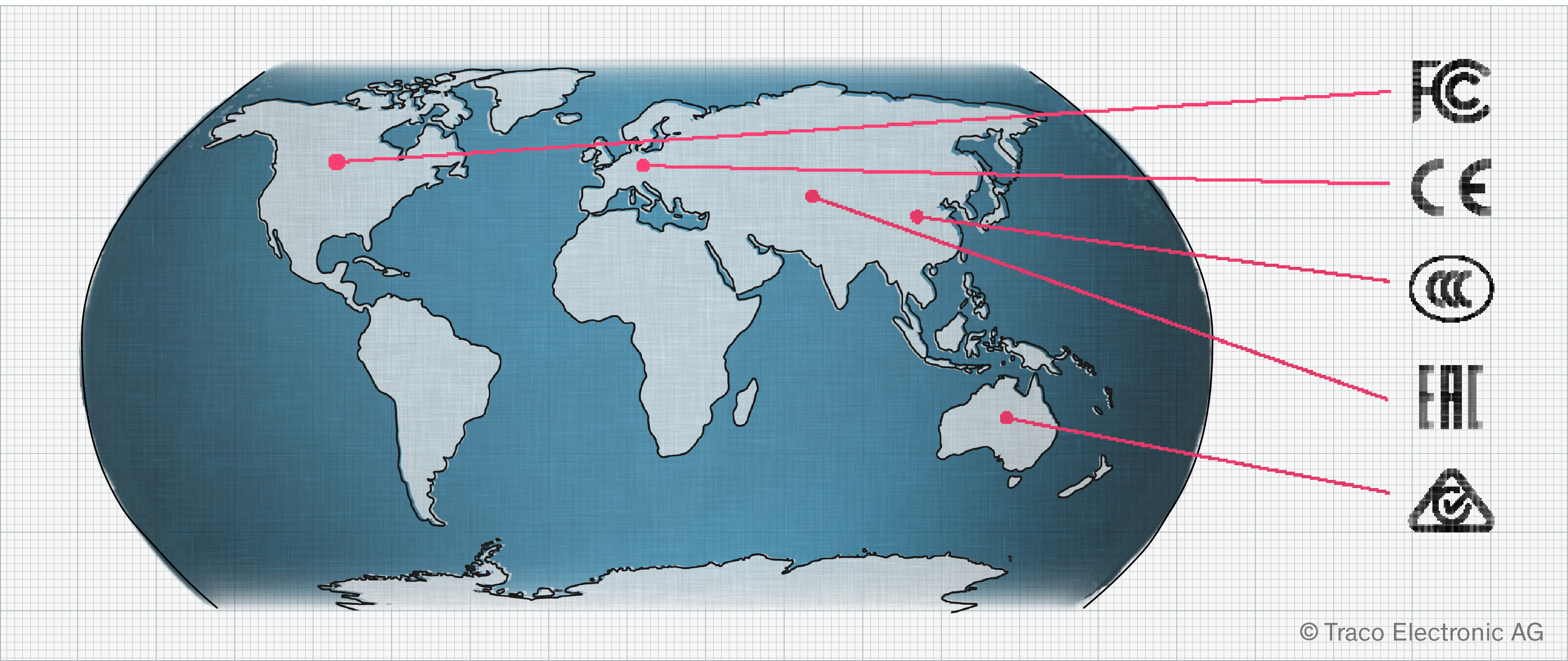

How do EMC standards around the world differ?

While international standards explain what to test for, how, and the limits, there are also local regulations. Before it is sold, there is also a need to prove that your product has been tested to the relevant EMC requirements.

In Europe, products that are likely to emit or be susceptible to electromagnetic energy must show compliance with the EMC directive. As this is very general, conformity can be assumed if compliance with the existing harmonized EMC standards has been achieved. Once a manufacturer has completed the necessary testing, conformity can be disclosed using self-declaration. However, devices designed to transmit radio signals, such as wireless phones, are treated differently. These fall under RED (Radio Equipment Directive) and not the EMC directive. For such products, the mandatory involvement of a notified body is required to attain compliance.

The United States has a similar approach with its Supplier’s Declaration of Conformity or SDOC. This is part of the Equipment Authorization Program. Emission limit classes are defined in FCC Part 15, which covers commercial products, or Part 18, for industrial equipment. Devices falling within the scope of these standards are required to be labeled appropriately. Amendments allow for testing using the same methods laid out in CISPR. Limits are similar to European standards, but devices must be tested using US-specific supply voltages during testing.

Across the rest of the world, there are, as is to be expected, further variations. In China, there is CCC, EAC for Eurasia, and RCM for Australia, to name just a few. Approval procedures naturally vary, although there are often similarities in limits and testing procedures. It should be noted that most deviations at the national level concern finished devices and equipment, not power supplies as components.

Will a Traco Power product meet my specific EMC requirements?

Because the majority of power supplies in Traco Power’s portfolio are designed to be fitted into a product or soldered to a circuit board, they are classified as components with respect to the EMC standards. We aim to fulfill the most relevant standards, enabling the use of our power supplies in most products, environments, and markets.

Naturally, there are exceptions. For example, EN 12895 covers EMC for industrial trucks, an essential standard for forklifts. While we don’t have power supplies certified to this standard, certification is possible and, most likely, is covered by the EMC compliance already achieved.

Using EMC-compliant components does not imply that the systems they are integrated into will pass EMC testing with flying colors. They only increase the probability of compliance. EMC is a complex topic, with wiring and loads impacting EMC behavior. Therefore, EMC needs to be considered at the system level from the start of your project. If you and your team are concerned about fulfilling the necessary EMC standards, it is worth requesting expert help as early as possible in your project.

To read more of our blogs, click here: www.tracopower.com/blog